The ‘Perfect’ Oil Production Report (and the Magic of ‘Proper’ Pumper Management…)

If you manage any facet of oil & gas production, this post was written for you. If you’ve ever struggled to lead your team of Pumpers in the field or wondered how to handle a difficult situation, this post is for you. If you find the people side of management difficult at times (and those Pumpers can be a tough bunch!), this post is definitely for you.

To be clear: this post isn’t about “management” the way most business publications talk about it.

To most folks, “management” means big organizational ideas like strategy, or finance, or organizational change. That’s not what this post is about.

Frankly, if you’re a foreman, production engineer, or an owner of an independent operating company, you don’t need to know a lot about that kind of “management”.

What you do need to know about is how to manage people.

This excerpt is about managing Pumpers. It’s about getting the most out of your field crew. Why do we need to get the most out of our field crew?

Because most Operators are very bad at that part of their job. And, it’s quite possibly the most valuable thing we do as an Operator. Isn’t that sad?

Most Operators are terrible at the most important thing they’re supposed to be doing: getting top performance out of the people that manage their assets in the field.

In a way, though, it’s not surprising. Lots of folks think getting a Master of Business Administration (MBA) will make them managers. But MBA programs don’t teach much about managing people (this is something I learned first hand…)

Part of the reason for that is that many of the professors have never managed a group of people with responsibility for their output – much less a crew of Pumpers!

Also, lease Operators aren’t easily placed into neat conceptualized models that can be analyzed and measured.

The funny part is, we’ve spoken to dozens of oil field supervisors whose “training” goes something like this:

“I got promoted from the field, and they didn’t tell me anything about what I was supposed to do or how I was supposed to do it. They just gave me a bunch of wells, half a dozen Pumpers to manage, and wished me luck.”

In fact, one new manager we worked with at a mid-sized operating company who now uses the GreaseBook for their production reporting software told us that the day she got promoted, her new boss handed her a set of keys to the filing cabinet where the well history was stored for all their assets, slapped down a sheet of paper with every Pumper’s name and telephone number printed on it, pointed to a spot on the map and said, “Your Pumpers operate here, here, and here, across these three Counties.”

THAT was her company’s onboarding process.

To us, this is mind-boggling.

The upside of this, however, is that whether you work for yourself or work for someone else, you’re not alone. That feeling you have that other Operators know what they’re doing but you don’t is wrong (almost everyone else doesn’t know either).

So, give yourself a break. Let yourself off the hook. You’re doing a difficult job, and you haven’t been given ample preparation.

That’s why we wrote this post.

So, What Makes an Effective Oil and Gas Operator?

There’s a lot of talk about what good operating is. When someone tells you they know how to manage oil & gas operations, or what it takes to get the most out of their wells, or how best to manage their Pumpers, or the smartest hack for getting all their monthly production reports organized, or the best daily production report template for excel, ask them, “How do you measure what a good Operator is, or does?”

If you don’t get a crisp answer—like the one we outline below—don’t take what they tell you very seriously.

We suspect you’ve known both good and bad Operators.

What makes them so? Is it what they do? How they think? Their personality? What they feel? How much time they spent on a rig? Where they went to school?

Think about this for a minute: How do you know someone is a good Operator? What is the definition of a ‘good Operator’?

When we ask these questions of folks in the industry, we get all kinds of answers:

- Their people like them.

- They communicate a lot.

- They’re smart.

- They care.

- They listen well.

- They are respected.

- They know the oilfield better than anyone.

These are good efforts, but they’re still incorrect.

Suppose a foreman or field supervisor reported to you who did or embodied all of the above. And, for the past three years, he had never achieved a single objective that the organization had set for him.

Would you describe him as a ‘good Operator’?

You’re damned right you wouldn’t.

Your first responsibility as an Operator is to achieve results. This may be the most important concept related to being an Operator. Your first responsibility is NOT to your team of Pumpers, your front line management, or any of your field contractors. It’s NOT to your people. You should NOT worry about them first. Your first responsibility is to deliver whatever results your business demands from you.

Whether you’re a reservoir engineer, and you have to “increase your economic recovery,” or you’re an accounting manager, and you have to “reconcile every drop of oil sold,” or you’re in charge of field operations and you have to “deliver, on time, on budget, in scope,” or you’re a production tech and you have to “collect and organize all gauge sheets, compile them into gauge reports, and submit your company’s Texas monthly PR Reports (or equivalent thereof)”, the thing that really matters is that you do what your company expects you to do.

For many oil and gas Operators, this creates a problem.

Why? Because you probably can’t name your top five key results that you owe your company this year. You most likely can’t tick off on your fingers, with ease, the key things for which you’re responsible.

You may be able to say, “The business demands that I focus in these areas,” but that’s not enough. You can’t quantify what is expected of you.

The problem with not having clearly delineated responsibilities is that you can’t make intelligent choices about where to focus. You begin to feel that “everything is important.”

You begin to “try to get everything done.”

Of course, you can’t, and you probably know that already, because you’re working long hours and never get everything done.

Okay, so results come first. Because Operators who produce great results are able to survive when other Operators can’t, and thrive when everyone else is just getting by. (But even reading this statement probably bothers you a little, because you’ve likely met at least one Operator who gets great results and does well whom you despise…)

There are Operators who put results so far ahead of everything else that they justify all sorts of behaviors to achieve those results. There are even industries—Wall Street comes to mind—that are more likely to tolerate this kind of behavior from managers.

When the ends justify the means for managers, bad things happen to the workers who report to them. A focus only on results far too often leads to abuse of those who work in the field.

That said, your second responsibility as an Operator who takes the long view is to retain your people effectively.

The smartest Operators understand retention (in addition to results!) is what builds the most profitable, resilient production companies. This is intended to be a brake against an unrelenting results focus that the price of oil forces upon your company.

That said, the brightest Operators – those that survive in any pricing environment – ensure that their team members don’t leave the organization.

Why? Because replacing employees is expensive.

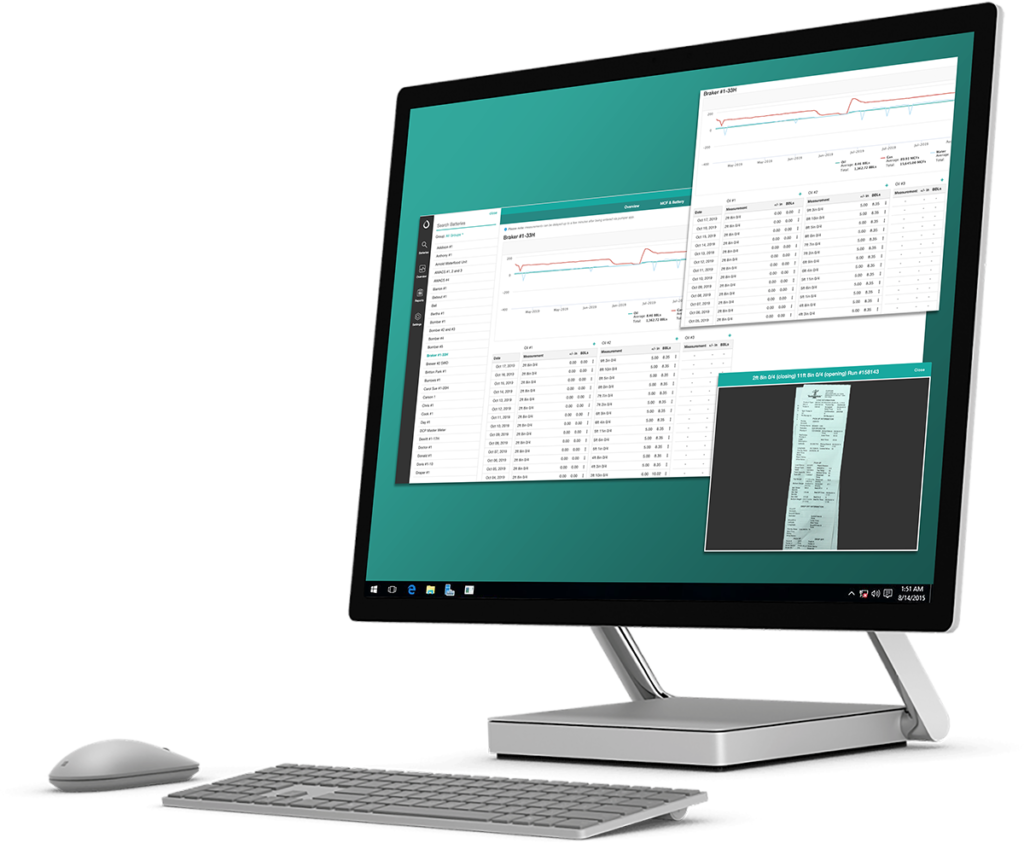

When someone leaves, there’s the lost work that had been planned for, the cost of interviewing in both money and time, the intimate knowledge of production properties lost, the likely higher salary that will be paid in the event of replacement, the time and expense of training the new employee, and the cost of less productivity by the new employee until that person can match the quality and quantity of work of the person who has left (yet another reason to have all your Pumpers, supervisors, and management working from some sort of production reporting software like GreaseBook. Why?

Because it acts as a shared repository of production information among everyone in your team, so (1) your production information doesn’t walk out the door when a particular person leaves, and (2) so you can spin up new folks very quickly…)

For today’s oil and gas Operator, it’s not enough to get results.

If you want to be an Effective Operator and if you want to maximize your job security (and, we would argue, your professional satisfaction), you’ve got to achieve these two metrics.

You’ve got to know how your organization measures results and retention, and you’ve got to choose to spend your time on things that achieve them.

What are the things that you can DO that are most likely to achieve them?

The four critical behaviors that an Effective Operator engages in to produce results and retain team members are the following:

- Get to Know Your Pumpers.

- Communicate about Performance.

- Ask for More.

- Push Work Down.

The First Critical Behavior: Get to Know Your Pumpers

First and foremost, don’t limit your communication to only following up when a Pumper doesn’t submit his oil production reports.

From all of our experience observing and talking with hundreds of independent oil & gas Operators, we now understand that the single most important (and effective) thing that you can do as a manager to improve your company’s retention and ultimately your company’s profitability is to spend time getting to know the strengths and weaknesses of your guys and gals in the field.

Operators who know how to get the most out of each individual member of their field crew achieve noticeably better results than Operators who don’t.

And, the most efficient way to get to know your guys and gals in the field is to spend time regularly communicating with them (and not just communicating through those daily oil reporting forms…)

Despite the fact that your primary responsibility is getting results, the most important thing you can do isn’t strategizing, task assignment, resource planning, or priority analysis. It’s getting to know the people who have the skills and who are going to get the work done.

For the record, an Operator can increase performance in the short term very effectively by using the power of his or her role as manager and threatening—and expecting—compliance. But if retention is thrown in as a required goal, that technique quickly sours.

Every person on earth expects and deserves to be treated as an individual.

Sadly, what most of us as Operators and field managers do (I know I did early in my career) is manage others the way we would like to be managed.

This is sort of the Golden Rule of non-experienced managers. You do to your crew what would make sense if you were one of those crew members.

The problem with this type of managing is that it only works (a little bit) with people a lot like you.

Perhaps you’re a field guy managing other field guys. There’s a pretty good chance that a good portion of your team is a lot like you…

If you used to be a landman and are now managing a crew of landmen, there’s a lesser chance, but still a good one, that some members of your team are a lot like you…

If you used to be a reservoir engineer and are now a production manager managing a host of Pumpers, well, there’s NO chance ANY of your Pumpers were EVER like you, but don’t despair!!

People and their behaviors are what deliver results to your organization. Not systems, not processes, not computers, not machines, and (gasp!) not apps.

Results are your primary responsibility. We are all unique—every one of us. What makes any of us as managers think that one size could ever fit all?

It might be easier, but it’s not more effective. And, if you’re worried that it takes a lot of work to be a good manager, this we’ll show you here that it really doesn’t.

At this point, if you’re like a good percentage of most folks, you’re probably thinking one of two things:

- “I think I know my people very well, actually.”

- “No need—I talk to my people all the time!”

Let’s take each of these ideas in turn.

First, “I know my people very well.” Perhaps you do, but the vast majority of managers who claim to really don’t. I’d guess you think you do, but we would bet that you don’t.

Here’s a thought experiment to judge your own knowledge of your Pumpers: what’s more important to you: your family or your work?

For most of you, the answer is family, and rightfully so.

Now, ask yourself the same question about your field staff.

What’s more important to them: their family or their work?

Without much thought, you realize that the answer is family first for them as well. And you’d be right—we’ve asked.

So, for your Pumpers, their family is more important than work. You say that you know your crew very well.

Here’s a test of that knowledge: What are the first names of all of the children of the people who report directly to you?

If you’re like roughly 95 percent of the managers we ask this question, you don’t know all of their names. A fair portion—maybe 40 percent—don’t even know how many children all of their employees have!

This isn’t a conclusive exercise, of course. But most people agree it’s a reasonable indicator—a fair proxy.

Think about it from the perspective of your personal life: your close friends all know the names of all of your children. That’s part of what makes them close friends. Your friends who are not as close know some of your children. And your acquaintances probably don’t know whether you have children or not.

If you failed the test, consider this: what makes you think you can get the last full measure of devotion to work out of someone when you don’t know the names of the people who are the most precious to them in the world?

Our guess is you probably can’t. If you’re smart and you work hard, you can do okay, but you’re missing the biggest leverage of all: a trusting relationship with those whom you manage.

If you’re responding to this discussion by thinking, “I’m not sure I like all the familiarity. I don’t want to be friends with the folks I work with,” then you’re not alone.

A lot of managers do a lot of their work with their team by email or text, or they see themselves as leaders rather than managers, or they say to themselves, “I didn’t need to be ‘managed,’ and I don’t want to have to manage my team; they should know what to do.”

We’ll have more to say on this, but for now, our first recommendation is this: spending 20 minutes a week with each of your directs isn’t likely to result in your becoming “friends” with them.

Now let’s look at the second item mentioned earlier: “No need—I talk to my people all the time!”

Many managers say this to us when we recommend that they spend focused, scheduled time getting to know their folks. They’re constantly in communication with their Pumpers through email, texts, and plenty of over the phone conversations.

In fact, some they feel like they talk to their Pumpers so much that they hardly have time for their own work.

Most Operators, however, have no idea how one-sided their conversations are with their team members. They have no idea how little influence those brief conversations actually have on building relationships.

Consider this: You thought about sending an e-mail but then realized you hadn’t spoken to your Pumper in a bit so you thought you’d phone’em up and ask him about whatever it was you needed. You thought it would be good to chat, as well, and see how he was doing.

You called him up and asked, “Got a second?” and what did your Pumper almost definitely answer?

“Sure!”

Well, your Pumper didn’t answer that way because he thinks you’re awesome. He answered that way because you’re his boss.

He knows you’re probably not there just to chat. You’re there because you want something.

That’s not a premise of a conversation that leads to a trusting relationship. It’s very likely that whatever chit-chat you engage in with him—“How was your weekend?” “How’s your spouse?” “What’s the latest with the kids?”—is heard by them, to some extent, as blah-blah-blah-I’m-going-to-get-to-the-real-reason-I’m-here-in-just-a-minute-blah-blah-blah.

I’m not saying that you don’t care about your Pumper’s weekend, or their spouse, or their children. I know you do, but they have a different perception of your caring about them than you think they have if you generally only ask those questions before you’re going to ask them for something (like, “where are last month’s gauge reports?!”)

Further, you don’t realize the extent to which your chit-chat with them is driven by you, by your agenda, and by what you want. It’s unlikely that many of your directs, when you drop a line and call them, will automatically feel comfortable talking to you about anything at all.

Results are your primary responsibility.

And, before we move on to a discussion of the second critical behavior, “communicating about performance,” it’s important to note that the four critical behaviors are not weighted equally. The four behaviors don’t each account for 25 percent of the total value of the four effective behaviors.

According to leading authorities on the subject, getting to know your employees (ie your Pumpers and field supervisors) accounts for 40 percent of the total value created by engaging in the four critical behaviors.

The Second Critical Behavior: Communicate about Performance with Your Pumpers

Would your performance improve if you heard more often from your boss about how you were doing? Most professionals, when we ask them that question, give a resounding Yes!

Now, if you’re like most Operators, you don’t talk to your Pumpers very much about their performance. You’re of the general mind-set that “They know how they’re doing” or “If I have a real problem with them, I’ll tell them.”

When you think about it, everything that’s done at a high level is done with a lot of communication about performance.

If you’ve ever paid attention to the advertisements for high-performance cars, you’ve noticed that they all say (and it’s true), “You can feel the road as you drive.”

That feeling is important in high-performance driving: knowing what the car is doing, what the road feels like. You have to adjust. The input about the road from the car that allows you to adjust is the feedback the car transmits to your hands on the wheel (and, according to drivers, your ass in the driver’s seat).

Think about professional sports: football, baseball, golf. All things being equal, if you’re like most fans, you’d prefer to watch professional games rather than high school games (unless your kid is playing).

The reason is that the caliber of play is much higher. You want to see something done well—done expertly.

At times, play at the highest level approaches beauty. One of the underlying reasons for that beauty is the athletes who perform at the highest levels of the game are provided with feedback about their performance for their entire career.

They know that creating and using the feedback that they receive will make them better, when it matters. Even the technology we use every day relies on communication about its performance.

Every machine we interact with—compressors, variable speed drives, disposal wells—all have numerous feedback circuits built into them. Either the machines or our Pumpers are constantly checking to make sure everything is within tolerance, checking variances, within normal limits, to avoid a significant failure.

About the only part of human endeavor in which feedback isn’t rapid, frequent, and timely is management. Just about the only place where feedback isn’t given, isn’t used, isn’t taken for granted is between Operators and their Pumpers (Owners: if you’re an owner or actively participate in your company’s wells, you’re the direct beneficiary of increased productivity…)

We all say that, as employees, we want feedback, but it usually just isn’t forthcoming.

When we talk to high-performing employees who rate their boss as outstanding, performance communications come up over and over again as a core reason. “He tells me how I’m doing.”

“When I do well, he says so.” “When I mess up, he quickly tells me, and we move on.” “I never need to worry about where I stand—she tells me.”

I’ll never forget one field supervisor telling me, “I didn’t know that communicating about performance was super important for getting great results in the field. I just did it because it was what I would have wanted. I didn’t like it in the beginning, but it worked, and I got over that.”

If you want high performance from your Pumpers in the field (read: less oversight, less mistakes, less chemical, less downtime), you’re going to have to talk about it with your Pumpers. It matters more than anything else, other than your relationship with them. And it takes more than just reviewing those monthly production reports together.

Do your own fact checking in Harvard Business Review, but performance communication accounts for 30 percent of the total value created by engaging in the four critical behaviors. This means that, if you build a great relationship with each of your Pumpers and talk with them about performance regularly, you’re 70 percent of the way to getting results and retaining your team.

The Third Critical Behavior: Ask for More

If you want great results and retention, you have to be willing to constantly raise the bar on performance.

It’s not enough, based on what we see, to simply be a caretaker. It’s not enough to accept from your directs what their “comfort zone” is. It’s not enough to let your Pumpers “stay where they are.”

I can assure you, your company’s ownership or investors don’t think anybody should be in their “comfort zone” very often.

Which reminds me with a current interaction we had with a small Kansas Operator that went something like this:

<<Email Chain Start>>

GreaseBook: Good news, Doug! Since we last spoke, we’ve had a huge influx Operators who’ve decide to jump on the app!

Like you, these Operators predominantly manage marginally producing wells, and wanted to keep better tabs on their production… And, once they saw GreaseBook, well, they decided to act on it.

Let me know what you’d like to do!

Doug: Am considering. Pumper has to agree to it. So far, leary. Forwarded your email on for him to at least consider.

GreaseBook: To be clear, you’re asking your Pumper to agree to something that’s going to give you more transparency and oversight of your business and his daily activities??

Don’t know too many folks (given the choice) who’d agree to that, Doug!

Doug: Just put him on board and he is doing a good job. It’s a partnership. Trust has to begin somewhere.

GreaseBook: We agree with you 100%, Doug.

And, in all of our working relationships, trust is implied.

We’re not in the business of undermining your Pumper’s trust. We’re in the business of replicating successful behavior. Again and again, without fail.

This is how we gauge. This is how we record our gauges. This is how we hold our purchasers and service companies accountable. This is how we send in our tickets…

The success of your operations shouldn’t depend upon your ability to find and hire trustworthy Pumpers, but upon your exemplary ability to systematize the management the affairs of these Pumpers.

Because, to the degree that you’re unable to replicate successful behavior, your ability to scale, sell, or simply take more time off is not only hampered, but blocked. Keeping you in that unfortunate state most oil and gas Operators find themselves in, looking for better and better people in the hope that they will bring better and better results.

With that, we wish you luck, Doug.

<<Email Chain End>>

**SIDE NOTE: Doug signed on a few days later 😉

Executives are in a constant state of stress and expect something similar (and sustainable) from you and your team. Executives are completely justified in thinking this way. If your company or industry is growing or changing (and “changing” includes “price volatility”), then every job is changing as well.

It’s the Operator’s job to figure out what the external change means for her group and to direct the performance of her group in ways that satisfy the needs of the company.

The ideal place for your Pumpers to be for maximum output/results is right on the line between distress and eustress, almost over the line into fear, but not quite there. They should have lots of energy but not panic.

The only way to know where that line is, for each direct, is to push each direct into moments of distress and pay attention to when they start to lose effectiveness. Everyone has his or her own point of diminishing returns. The way you do that is to ask for more.

If you’re an experienced manager, you’ve probably dealt with a Pumper who says, “I’m happy where I am.”

Lots of new managers have been stumped by the average Pumper who doesn’t want to improve and doesn’t want a promotion, yet is still “technically doing the job.” Not well, mind you, but the Pumper is meeting the standards, and submitting those oil production reports on-time.

As Operators, we’re responsible not just for the status quo, but for improving the performance of the whole team. The best way a team’s performance improves is if each individual’s performance improves (there’s also the Secret to a (Highly Profitable) Digital Oil Field Management System which can most definitely help – but that’s another story!)

If your team’s goals are being raised (and, if they aren’t right now, I assure you that someone is thinking about raising them), you need to get more out of everyone to meet those higher goals.

So, the Pumper who says he is happy where he is fine, for now.

In a year, though, his job will have changed enough—and the standards will have risen enough, because in this industry with the EPA and new mandates coming down the pipe, the standards have nowhere to go but up—that his performance will have declined relative to the needs of the job.

The effective Operator is always, in one fashion or another, asking for more. To be an effective Operator means encouraging and inspiring all of your Pumpers to higher performance even when they say they don’t want to, they’re too old, or that’s not the way it’s always been done—because you know the company needs that to stay in business.

If we had to assign it a number, “asking for more” accounts for roughly 15 percent of the total value created by engaging in the four critical behaviors of effective operating.

The Fourth Critical Behavior: Push Work Down

While the first three parts of effective operating create value for the team, “pushing work down” creates capacity for the organization.

Put differently, you can produce results from your team with only the first three parts of the first three critical behaviors, but pushing work down creates growth potential for your entire organization.

What does it mean to “push work down”?

Here’s a simple way to think about it. Suppose there’s a task that both you and one of your directs can do

Example:

- writing out daily oil reporting forms by hand on a traditional gauge sheet or gauge report

- faxing, mailing, or submitting via email, then

- paying a production tech or admin to chase-down, transcribe, and compile these reports into something useable.

- You or your in-house staff does this, but your Pumpers—COULD do the task.

If I were leading a class in Managerial Economics 101, based on the above situation, I would give a quiz: “If the above situation is true, which of the three of you—your Pumper, you, or someone in your office—SHOULD do the task, and why?”

If you don’t know the answer immediately, it’s okay. But just so you know: in Managerial Economics 101, there is a right answer 😉

Essentially, the Pumper should do the job and not the Operator, the admin, the engineer, or the owner, because Pumper labor is already a direct cost of us doing business.

If we can achieve more productivity with the same cost (many times less cost, depending on how your company’s daily oil production reporting workflow is structured), for all but the most important things we do, we should do so.

To keep your costs as low as possible, GreaseBook runs on whatever device your pumper already owns Apple, Android, or Microsoft.

Why is this true? Because Pumpers are already doing it anyways.

Now, a lot of Pumpers would say, “Well, yes, technically I’m already doing it to a degree, but that’s not the whole story. I have my own work to do! I don’t have time for you to push work down to me. I’m already fully busy.”

They’re right, but that’s not a defense against work being pushed down. Why? Because the question really isn’t whether people are busy or not.

All workers are busy, aren’t they?

By using the defense of “busyness,” no work would ever be transferred to anyone else, and we would all be stuck in a weird productivity stasis (which, due to the link between productivity and profitability, and the inevitability of change, is the equivalent of an organizational death spiral).

Did you know?

Did you know that when using Palm Pilots, Excel sheets, or other laptop software, it can take a full hour each day to log a 40-well route. Using the GreaseBook, entering 40 wells takes less than 12 seconds per well—that totals less than 8 minutes for an entire 40-well route!

GreaseBook also keeps pumpers from fat-fingering data by notifying them when they have entered negative production or something doesn’t look quite right.

The result?

Pumpers deliver clean data to the folks in the office and free up more time so they can focus on their route.

Now, that’s leveraging your pumper!

Clean data. Less admin work for everyone. More time pumping.

The question becomes, in a world in which everyone is busy with too much to do, “What work is most valuable to the organization?”

That’s the work we have to get done, right?

And, in a general sense, the more important work of the organization is being done at higher levels.

Side note: If you’re a Pumper, that probably irritates you, but we’re not talking about adding to your workload… we’re talking about shifting away from how things have always been done so that everyone else in the company can benefit.

Now, instead of calling a Pumper to ask where a run ticket is, your in-house staff can spend that time finding discrepancies, reconciling oil sales, and clawing back any money left outstanding.

For the in-house engineer, she no longer spends time extracting data out of those oil production reports and working it into something useful, she now has production graphs and notes that actually make sense and are easy to work with.

What this means for the Operator is that we have to learn to share our work (that which we can share, which is probably most of it) with our Pumpers (which is precisely the reason that next gen Oil and Gas Production Software makes it hurt so good…)

Pushing work down accounts for roughly 15 percent of the total value created by engaging in the four critical behaviors.

The four most critical behaviors a manager can engage in, to produce results and retain team members: Get to Know Your People. Communicate about Performance. Ask for More. Push Work Down.

Without these critical behaviors, and without replicating successful behavior of our Pumpers and systemizing the management of the affairs of these Pumpers through standardized oil production reports, all we’ve got left is “doing it, doing it, doing it.”

Unfortunately, this is the tactical reality of almost every independent oil and gas Operator. Wake up, it’s time for us to grow beyond that.

Quick Recap:

Historically, oil and gas production software has been built for management, not the pumper. This technology does not work for pumpers. Instead, it creates work for them that hampers the data gathering process in many ways.

Operators should strive to adopt oil and gas software that leverages the pumper’s time, eliminates admin tasks, automates data capture, and further engages the pumper in strategic ways.

Effective oil and gas production software creates better pumpers by capturing and creating a shared database from which your pumpers (new and old) can work.

By enabling management to focus on higher-level strategy rather than the day-to-day minutia of their operations, oil and gas production software developed for easy use by the pumper dramatically increases ROI. In fact, it’s not uncommon for operators to report a 2-4% increase in production and a 10% reduction in operating overhead.

GreaseBook works beautifully on any computer, PC, or Mac.