Oil and Gas App -celeration: A Killer App for Oilfield Operators

Today, we’re delighted to write about a particular subject that is very near and dear to our hearts: why most oil and gas operating companies don’t work, and what to do about it.

I don’t know if you’re familiar with the statistics, but it’s very important we understand the condition of the independent oil & gas operator as it is (rather than as people would like to think it to be…)

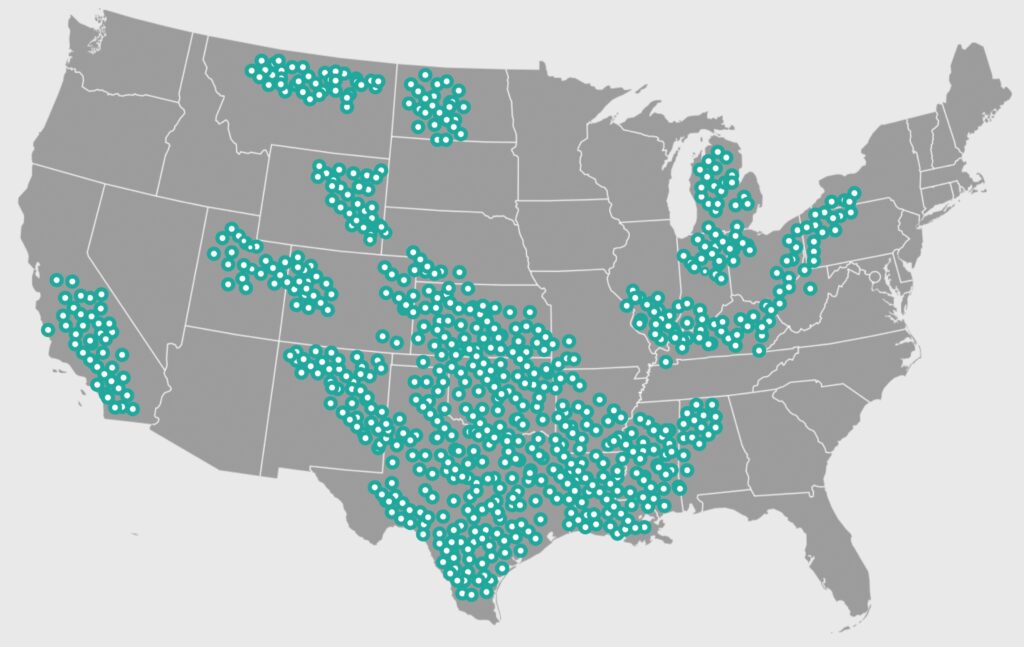

According to the IPAA’s Economic Report on the ‘Profile of the Independent Producers’, there are 9,000 operators in business in the oilfield today.

And, the average number of workers employed across these 9,000 operators is 12 people. That said, we’d classify 90% of oil and gas operators as ‘small businesses’.

What’s interesting, is each year hundreds of independents open up shop with the absolute certainty that they’re going to change their lives, change their fortunes, become completely independent, and “get rid of the boss”.

Unfortunately, what ends up happening is they go to work for a lunatic: THEMSELVES. And, in the process create a wake of disaster (are you mad yet? Good, because you should be…)

You see, what these operators don’t understand are the statistics… they don’t understand just how much the odds are stacked against them. And, if they understood what it meant to go into business for one’s self, how challenging it can be produce oil and gas, what it means to be a small operator, they’d pile their money back into their 401K, return the money of their investors, and keep the job they’ve got.

And the reason we’re going to suggest that we have a problem in oil & gas today – and it’s an extraordinary problem of the dimensions most people simply don’t realize – is the people going into business aren’t who we think them to be…

So, Who is the Oil & Gas Operator?

According to Bloomberg, 80% of small businesses fail in the first 5 years. So, of the several hundred oil and gas operators who got their start last year, 80% will have failed by the time they reach their 5th anniversary.

Now, for those of you who’ve been operating for longer than 5 years, don’t breath a sigh of relief just yet because here’s the good news: of the remaining 20% of business that made it past this 5th year watermark, a full 80% of those businesses will go out of business in the following 5 years.

So, if the first 5 years don’t kill you, the second 5 absolutely will.

Nice to think about, isn’t it?

So, what is it that causes all this failure in oil & gas?

Is it the economy? The EPA? Is it that we just can’t find good people? Maybe your lousy business partner? Could it be your lack of capital? Or, the price of crude?

We’re going to suggest that none of these causes are the reasons operators fail in this business…

In reality, it has everything to do with something significantly deeper and significantly more important and most operators seem unwilling to look at the fact of it.

Allow us to suggest most oilmen have a set of skills that got them in the business in the first place. Whether they be an engineer, a landman, geologist, geophysicist, whathaveyou – they’re essentially a technician.

And, each and everyone of these technicians believing that because they understand how to do the technical work of operating oil & gas wells, that they also understand how to run a business that does that technical work.

And it couldn’t be further from the truth.

Knowing how to do the work in your operations has nothing to do with creating an operating company that works. Much less, one that works for YOU.

And, this is the fatal assumption behind the failure of almost every single operator you walk into, because the owner of that business, the founder, the oilman does not start a business as an entrepreneur would.

The founder of that business starts the business for absolutely the wrong reasons…

From Sharecropper to the Pages of Forbes Magazine

We’d like to talk about a man whom we’re sure you’re familiar with. He’s on the list of the nation’s 10 most wealthy oilmen.

On that list, you have such names as the Koch brothers, the Hunts, George Kaiser and the like.

However, of the 10 wealthiest oil and gas men (and women), only 2 are self made:

Jeffrey Hildebrand of Hilcorp Energy (Houston, Texas) and the other who’s the focus of our story today: Harold Hamm of Continental Resources in Oklahoma City.

When we talk about Harold Hamm while addressing small and mid-sized operators, most of them roll their eyes and ask, “what the hell are we talking about Harold for? I mean, I’m not Harold, I’m not Continental Resources, and quite frankly I don’t wanna be Continental Resources…”

We get it. However, we ask that you entertain something for a moment: will you agree with us that Continental Resources is a relatively successful company? You’ll most likely agree with an emphatic, “Yes”.

Last year, Continental Resources extracted 82,000,000 barrels of oil. That’s 225,000 bbls of oil per day, 9375 bbls of oil an hour, 156 bbls of oil a minute.

Harold makes more oil in a minute than a most of us reading this article will produce all day.

At $50 oil, that’s $11 million/day, every day.

Can you see that? How’d he do that??

Love him or hate him, that’s not bad for a dude who was born in Lexington, Oklahoma, to a family of sharecroppers who started his professional career as a gas station attendant.

You gotta wonder, what did that guy know?

Harold knew one critical thing that separated from everyone else reading this article: there is absolutely no difference between a big business and a small business.

A big business is simply a small business that did the right thing. And, if we’re able to act in the beginning as if this business were already complete, only then would we have a shot at replicating Harold’s success.

Harold didn’t go to work in Continental Resources, he went to work on Continental Resources to replicate the picture of the future Continental he held in his mind. Let me say that again because it’s so critical: Harold didn’t go to work IN Continental he went to work ON Continental oil to replicate the picture of the future Continental he held in his mind.

Ladies and gentleman, what I’m suggesting is this: it’s not the tech, not the tool, not so much ‘the digital oilfield’ that 99% of independent operators are missing in their operations today, it’s the entrepreneurial mindset.

The point is so very simple, but so extraordinary difficult to grasp. The entrepreneur has a picture of a business ‘out there’ which she works toward, an almost tangible vision they can see and hold out in front of them.

Most oilmen are their business. They can’t separate themselves from it. They get up and they do it. They get up and they do it. They get up and they do it. They can’t imagine it getting done without them.

Being engineers, geologists, landmen they have an extraordinary focus on the work at hand.

But, being an entrepreneur means having an extraordinary focus on a vision of a business that works.

So what’s necessary to change your operations?

It’s quite simple really: change your point of view.

What needs to be done is to create an operating company that works. To go to work ON your business not IN your business to get a business that works without you.

If you can find a way to produce a business that works without you, your life would change overnight.

That said, today we’re going to take your out of your experience and put you in a totally new one.

Ladies and gentlemen, I’m going to suggest that ‘systemizing your business’ is the solution.

Said differently: whether it’s an oil and gas application or oil and gas app, the system runs the business and the people run the system.

Understand, systems are the leverage every oilman needs, yet so few have.

Command and Control Your Operations, through Oilfield App or Otherwise

Through systems – or even better, an oil app of sorts – you’ll have the opportunity to command a ‘turn key’ operation. What’s a turn key operation?

A turn key operation is a system of integrated components that work in an absolutely predictable fashion every single time.

And, you’ll find 4 levels of components baked into any turn-key system worth its salt. Let me describe them for you:

The First Component

The first level or foundational level, is ‘how we do it here’ via oilfield app, or otherwise. What’s true of every exceptional company is that they have a way of ‘this is how we do it here.’

This is how we do it at Amazon. This is how we do it at Apple. This is how we do it at Google. This is how we do it at Uber. This is how we gauge. This is how we record our gauges. This is how we hold our purchasers and service companies accountable. This is how we submit our tickets. (And, which is precisely the reason the right oil and gas production software makes it hurt so good…)

Funny enough, this is precisely what differentiates these companies from everyone else. Why?

Because nobody else has a ‘way of doing it’.

The Second Component

The second component is the system by which you recruit, hire, and train people to use the first system.

How do we recruit and hire our pumpers? Our production techs? Our admins?

Because all the companies outlined above have just such a system. Because the biggest problem in oil & gas operating is that we build businesses around people rather than around functions. And, when a person leaves the business collapses.

Oilman #1: “OMG, Sandy left! Now whadawedo?!”

Oilman #2: “Heck, let’s get another Sandy! What did Sandy do?”

Oilman #1: “EVERYTHING!!”

So you run an ad:

WANTED: Someone to do everything. $15.00 an hour. Expert at production, expert at accounting, expert at run ticket reconciliation, expert at cracking the whip on our pumpers, geo tech, expert at dropping my shirts off at the dry cleaners and expert at picking them up…

And you know who answers that ad?

Not a soul.

So, you hire 3 people to replace Sandy, and you say to yourself, “oh, i didn’t realize. . . “

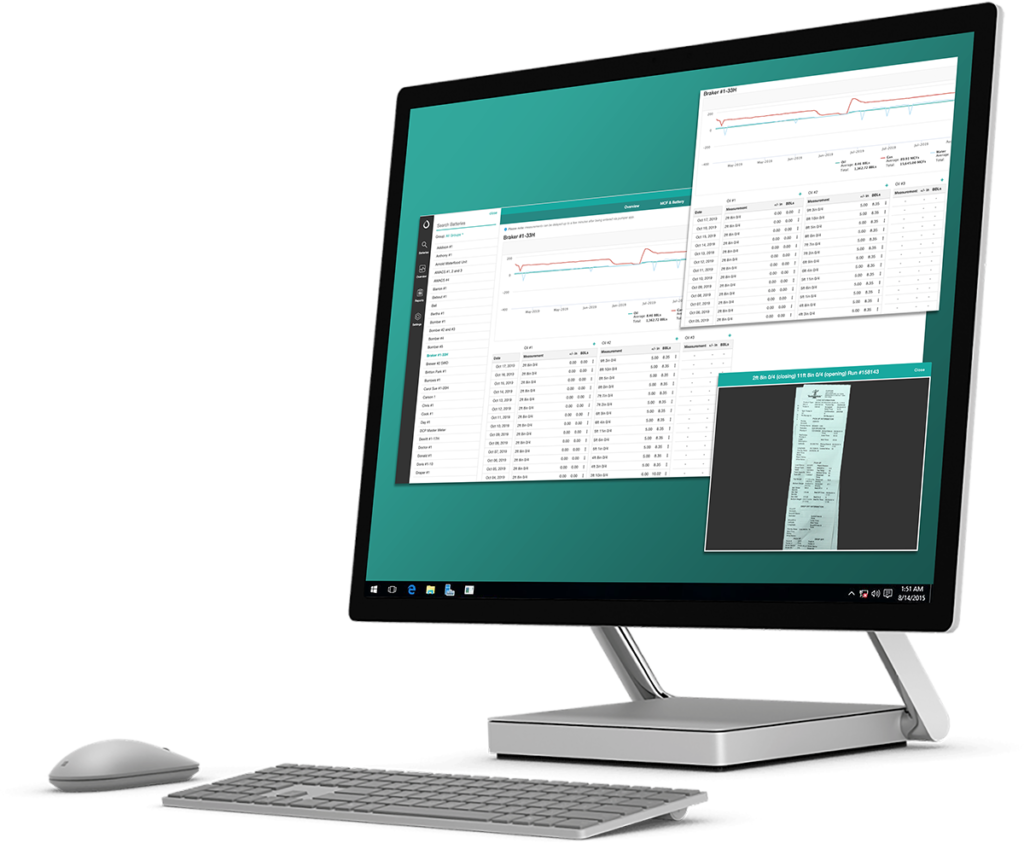

However, with the right oil and gas app in place, an oil field app that’s simple to use and systematizes the dissemination of data among everyone on your team, your next Sally, Randy, or Joey can be geared up and start contributing not in a matter of weeks or months but a matter of minutes.

That is the beauty of the system.

The Third Component

The 3rd system is a system by which you manage these first two systems. This is your management system. To do what?

To monitor the USE OF THE SYSTEM, to discover flaws in your oil operations, in your people. Why?

Because the most extraordinary operators we know of are focused on finding a better way. To do what?

To do what they do. Which is?

Produce oil and gas in the most cost effective manner possible. To maximize profit.

And only through your management system is the oilman able to achieve a sense of control that he doesn’t have anywhere else.

He can’t control the price of oil, that said he must control the only thing he can: his operations. His system! The clean workings of his machine.

And unless you like increasing your overhead and throwing more bodies at a problem, the best way to obtain transparency throughout your operations is through data… data that only an oil and gas app can provide.

The Fourth Component

Finally the 4th system, in this hierarchy of systems is what we call the Business Development System. The system by which we are innovating, quantifying, and orchestrating what needs to be done in our business to reach Maximum Profit.

Innovation: finding a better way.

Quantification: measuring just how well it works. You have to quantify to be able to improve.

Orchestration: making sure that it works that way every single time by eliminating discretion or choice at the operating level of our business amongst our pumpers, admin, production techs, what have you.

Fortunately, this is what oil and gas apps do best. Because unlike humans, only software can accomplish the same tasks millions of times without making a mistake, without becoming distracted, without relinquishing its accountability (read here on Field Data Capture and the secret of the most cost-efficient Oil Producers in the game today…)

By the way, in no way are we advocating getting rid of people through use of oil field apps. We’re simply suggesting to further leverage the human element via software and more progressive oilfield technology to enable you to extract the most amount of profit and efficiencies from your team as possible! (check out this write up we did on a list of apps we’ve observed some of our clients using that function as perfect companions to those who work in the oil & gas industry…)

We make a point of this because traditionally, how have operators solved their growing pains? They’ve simply thrown more people at the problem. And this is precisely where we get into trouble…

Understand, we must refine the system before adding people. Adding people to a refined system multiplies output; however, using people as a fix to a poor system multiplies your problems

If you’re simply delegating to others before reevaluating the process, you’re now simply wasting somebody else’s time as opposed to your own.

To keep your costs as low as possible, GreaseBook runs on whatever device your pumper already owns Apple, Android, or Microsoft.

An Oil and Gas App for Operators

After seeing what was missing in this picture, it became apparent to us that nobody was asking the question, “what’s wrong here?”

And to be quite frank, this got us fired up to go out and do something about it…

To build a world-class system, an oil and gas application that we could bring to any small operator for the cost of a minimum wage employee. To do this we had to invent the perfect system. Something simple, perhaps something in the form of an oil field app.

We had to take oilfield technology that was a commodity, and turn it into a product. And we felt it was best to start at the foundation of it all: the Pumper. Thus we set out to create the best damned pumper app possible through which we could not only maximize the pumpers contributions but increase the take home pay of the oilman who employs this pumper.

And, we’d need to bring this oil and gas application to every small operator, not to get them to do what we know how to do, but to get them to do what they need to do to produce more oil, to do it for less money, with less people, with more calm.

Because to get where we’re going, we’re going to suggest that you go to work on your operations as those you were going to operate 10,000 wells. That’s right, I’m going to suggest you go to work on your operations as if you were going to scale up to 10,000 wells.

And, as opposed to going to work in your business every single day, go to work as though you were going to create this perfect little prototype that you could scale over and over and over again, and put it into the hands of ANY DUMBY.

Are we suggesting that you’re going to hire dumbies, or that anyone reading this article is a dumby? Of course not! (For example, check out this article on how to empower your lease operators with a pumper app to bring organizational results…)

What we’re suggesting is that you do not need to hire experts if you’ve created an expert system that leverages ordinary people to produce extraordinary results. And that’s the secret of success behind every extraordinary entrepreneur.

You’re going to have to think of your business as a prototype to run operations of 10,000 wells. And guess what’s going to happen?

You’re going to have to solve problems today that you’re going to confront when you acquire well number 2, 20, 200, and 2000. You have to begin to think of the end product of your effort.

And the problem is most oilmen don’t – they simply go to work and resist the call to mobilize their workers.

How exactly do you go to work with the end product in mind? Let’s just imagine you’re going to go to work today on your business as opposed to in it. Let’s just imagine that today is going to be the very first day of this new business. Let’s just imagine that you’re going to create a system that works, you’re not going to create people that work.

Great businesses don’t happen by accident. What every great entrepreneur understands is that if I have to build a business built upon great people, I’m in trouble. Why?

Cause they’re gonna end up going into business for themselves.

What we’re looking for is what’s out there by the droves: ordinary people. People who want an extraordinary place to work. Where they can have an opportunity to grow. And, we’re gonna give them that place to build their own personal career USING A SYSTEM in the form of an oil app. What’s more is these folks can help us to innovate that system, to give us feedback on this oil and gas app, to make it work better and better and better.

For whom? For the owner and partners of the company, of course. However, perhaps more importantly, for the employees in that company. Why is this important?

Because we work in a volatile industry. And what does a better system provide?

Job security.

Because the next time the price of oil takes a dip – which it undoubtedly will – YOU won’t have to sit there wondering: “is my job in jeopardy?’

Because through your help in working ON the system, you’ll have lowered the marginal production costs, otherwise known as the point at which we shut our wells in.

Basically, if Operator A manages 100 wells with a staff of five people and Operator B manages 100 wells with a staff of twelve — all things being equal — Operator A wins. His investors win. His employees win. And, the company will carry on in nearly any environment.

Sub $40 oil ain’t party time, but your company isn’t closing it’s doors either.

So the idea for the owner, the idea is to essentially build a money machine. One that works and spits out cash even when he’s not there.

And, when you’re finally done with this thing, you have a choice, (1) you scale up as big as you want to and instantly stand out in the oil patch like Harold Hamm, or (2) hire yourself a general manager teach him the system and get lost on a boat somewhere.

Just call in every Tuesday and ask, “What are the numbers?” You know what the numbers have to be, right? RIGHT?!

Ask most small operators what the numbers are and they look at you and they’re blank. “What numbers? Who’s got time to count? I’m working!!!!!”

Get yourself a manager, the manager will run the system for you.

Finally, one thing I’ve found to be true from talking to thousands of operators in this business, is that 90% enjoy the hell out of what they do. Knowing that, once you’ve rolled out this system you yourself can go to work IN the system with the only difference being is now you produce 10X the result with ⅓ of the effort.

Because you’ve got a system that works and you’re working it.

So, what I’m really suggesting is a very simple principle: that the reason most independent operating companies don’t work is because the people that own them DO.

And they’re doing the wrong kind of work.

And if they were going to go to work ON their business as an entrepreneur would… with a picture of how the business is going to work without you… to begin to construct it, manufacture it, engineer it, systematize it, can it, so that you could literally hold it in your hand, see it whole, see the business as apart from you rather than a part of you, then what I’m suggesting is that your life would change.

If you could do that in your business so that you don’t become a producer of oil, it produces oil and you manage it.

What is ‘it’?

Personally, we believe ‘it’ is some manifestation of the digital oilfield, GreaseBook or otherwise. But that’s for you to decide. Why do this as compared to that? Because it lowers our operating overhead.

Hold on a sec, how do I lower my operating overhead?

Well, you’d better find out my friend. Because that’s the business of today’s oilman. The market is ruthless, and unless you figure how to produce what you got for less, everything we learned here today becomes irrelevant.

If you get it, and you want it, and you do it this way, everything will change. And mark my words, you’ll be able to carry on in almost ANY pricing environment.

To Recap:

Most oilmen have a set of skills that got them in the business in the first place. Whether they be an engineer, geologist, field supervisor, or geophysicist – they’re essentially a technician. And, each and everyone of these technicians believing that because they understand how to do the technical work of operating oil & gas wells, that they also understand how to run a business that does that technical work.

There is absolutely no difference between a big business and a small business. A big business is simply a small business that did the right thing.

Systems are the leverage every oilman needs, yet so few have. And, we must refine these systems before adding people. Adding people to a refined system multiplies output; however, using people as a fix to a poor system multiplies your problems.

By enabling management to focus on higher-level strategy rather than the day-to-day minutia of their operations, oil and gas production software developed for easy use by the pumper dramatically increases ROI. In fact, it’s not uncommon for operators to report a 2-4% increase in production and a 10% reduction in operating overhead.